Carbon Steel – We Salute You!

There are a great number of steel grades in the world, all with their own quirks, deviations and peculiarities, but sometimes it feels that some of the guys out there are taking all of the glory. While stainless steels are incredibly useful for fine surgical tooling, professional kitchens and the bodies of Doc Brown’s time-machine, there are a number of other steels that do an awful lot of work.

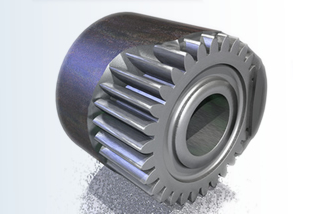

We’re specifically talking about carbon steels, which themselves come in many different grades and have a specification for every purpose. There are a number of different grades of carbon steel and some are a lot more technically advanced than you may give them credit for!

Mild steel is a generic term for low carbon steels, typically carbon content is between around 0.08 and 0.25%. This tends to be the first steel that many people come across, as it’s the one most commonly used in schools. It’s easily workable but maintains a good tensile strength; it’s also quite cheap and is readily weldable, making it ideal for teaching pupils the basics of handling and joining metals. Mild steels with a particularly low carbon content are suitable for case hardening, where a harder outer crust forms over a softer centre, allowing it to absorb impacts more readily than a steel that’s hard to the core. Interestingly, mild steel remains in common and widespread usage; British coins are copper-plated mild steel and the very first stage of the BMW mini – known as ‘body in white’ – is a mild steel framework.

Medium carbon steels can be further hardened and tempered to increase tensile strengths. They can be flame or induction hardened for extra strength, but there’s a risk of surface decarburisation from reaction with the atmosphere when it’s rich in oxygen. Medium carbon steels tend to be used in shafts, axles and crankshafts where reasonable strength levels are required but alloyed steel is too expensive.

“55 Carbon” steels are between 0.5% and 0.6% carbon content and they have moderate wear resistance. Any hardening needs to be done carefully to avoid surface cracking and it doesn’t react well to welding.

Beyond 55 Carbon steel, there are a number of spring steels, including which offers greatly increased hardenability.

The wonderful thing is that these steels all have a perfect usage and they do so without involving huge alloying and working costs. They offer all of the useful features that we need from our products without raising the cost and making common items effectively unaffordable; they do everything we ask without making a fuss. Carbon steels are, in many respects, like Shirehorses; unlikely to ever win the Grand National but they’re able to perform some very impressive acts.

Hi Rob,

We have an application with 4330V for which you recommend Forge/anneal/Machine/stress relieve/harden and temper. We have threads on the component. Does that pose any specific problem during hardening? is scaling a problem in post machining heat treatment processes?